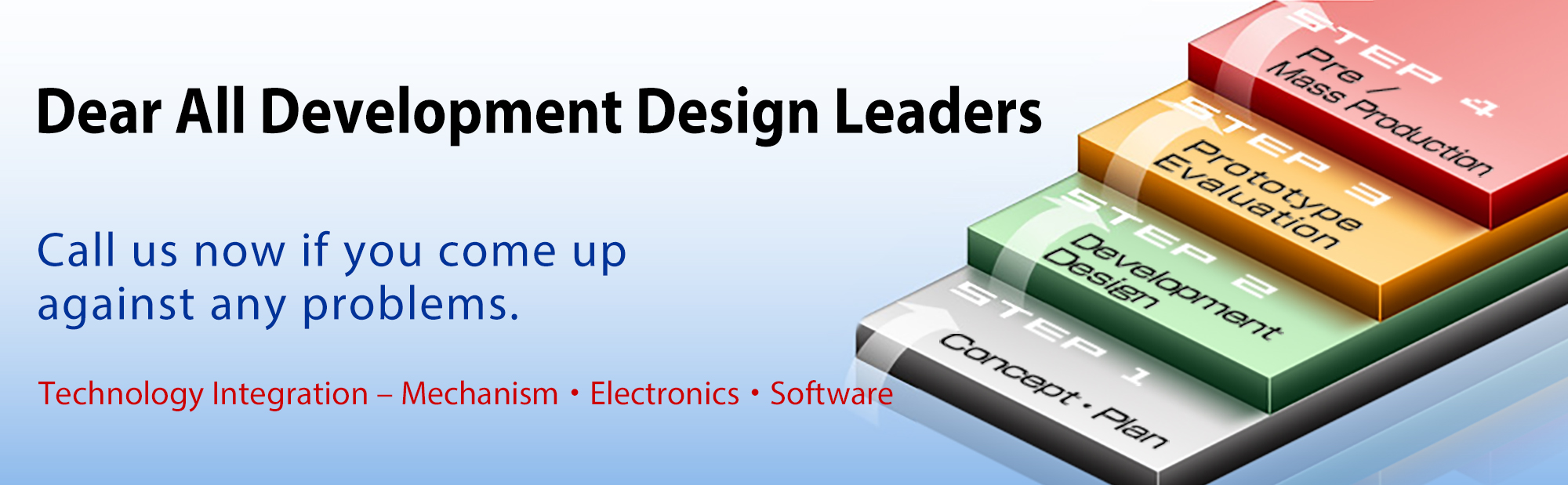

Our expertise and experience cultivated over the years in Japan allows us to offer our comprehensive technologies into which mechanism, electric circuits and software are combined. We are sure of our ability to assist you with your development of products.

Machinery / Mechanism / Casing / Mold Design

Circuits / Microcomputers / PCB Design

Pre / Mass Production

Software Development

Design / Technical Assistance

New Product Planning

Project Management Supervision

Business Assistance for engineers

Drawing data Conversion (2D / 3D)

Nearly end-of-life mold maintenance and drawing modification

Paper drawings computerization

We can offer one-stop solution by mechanical / electrical / software technologies.

By One-Stop Solution, ASSISTEC can undertake consulting assignments as the whole production process starting from planning to manufacturing.

We also accept partial contracts; such as designing and / or prototyping only. We have a desire to contribute to our clients by assisting in developing new products.

A proposal, in which the functionality and performances you are going to realize are detailed, is an embodiment of the designer’s imagination. ASSISTEC can assist from that primary stage. Market research, patent survey, production of project proposals and presentation documentation, and others, these are all TIME-CONSUMING and BURDENSOME work and keep you from further business opportunities, we want to assure you that ASSISTEC can take over this work. The following are merely some of the examples we have assumed on behalf of our clients so far. Rest assured that you can leave any chaotic, messy, boring assignments to ASSISTEC.

Proceeding with practical design according to agreed Product Planning scheme.

On demand, prototypes are made to the required specifications. We will report to the client the test results on functionality, performance, environment, electrical and mechanical endurance, and the like.

In this stage, we make final confirmation on quality of production parts, production and assembling systems.

Design of 360-degree infrared ray control casing, which is capable of controlling any electric appliances.

Prototyping of Super Thin Display Device about 2mm thick with EL panels.

A compact excited state light blood analyzer which enables it to analyze the blood on the spot sampled beside the bed.

Futuristic Lightings.

An electrical circuit to control a high current while suppressing temperature rise in electrical components.

Optical Fiber Transmission Line Damage Inspection Device.

Smoke and/or flame sensor inspection device.

MHD (Magneto-Hydro-Dynamics) linear power generator.

Measurement by detecting the light reflected from the end edge of optical fiber.

Development of Wireless Information Transmission System.

The freshness of leaf vegetables can be recovered by jet-spraying water columns with ionized air from the nozzles in the washing water tank.

Development and production of Non-Contact Card Reading Device to FeliCa standard.

These are just some of our achieved works shown on this page. In our archive, we have quite a number of our developed projects so far.

If you desire to know further what else we have developed and whether we can assist you to develop what you are planning, please feel free to contact us.

ASSIST TECHNOLOGY CO., Ltd.(ASSISTEC)

We aim to contribute to society by creating client dreams into reality through our comprehensive technology - mechanism, circuit and software.

+81-(6)-6781-7021